How to Set Up Your First Hand Tool Woodworking Bench

Are you ready to dive into the world of hand tool woodworking? One of the most important first steps is setting up a dedicated woodworking bench. A well-designed hand tool woodworking bench is the heart of any woodworking shop, providing a solid, stable surface for all your cutting, planing, and assembly tasks. Whether you’re a beginner or a seasoned woodworker, this guide will help you understand the essentials of setting up your first hand tool woodworking bench, from choosing the right bench to organizing your tools efficiently.

Why a Hand Tool Woodworking Bench Is Essential

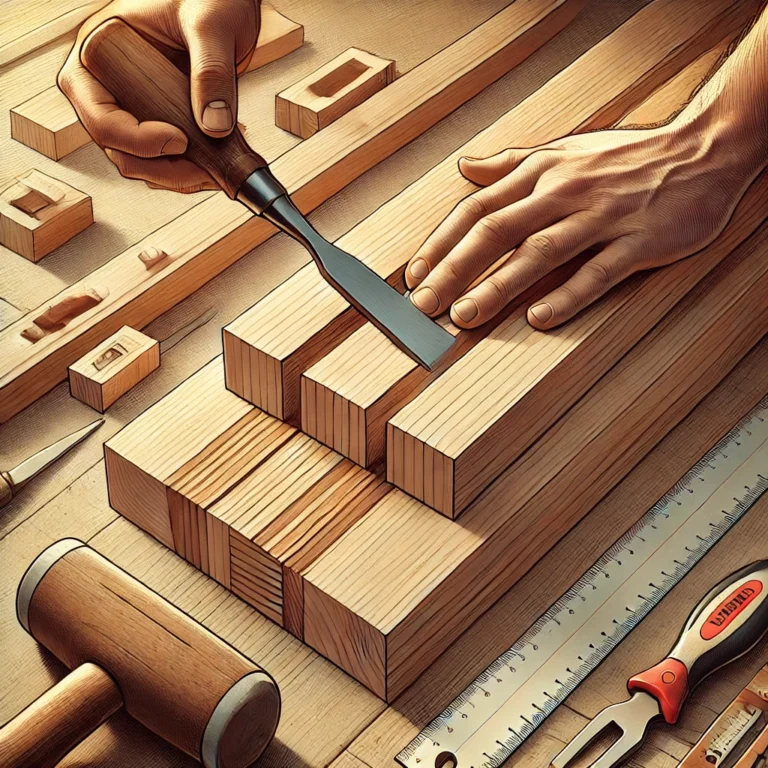

Before we dive into the details, it’s important to understand why a dedicated hand tool woodworking bench is so crucial. Unlike power tool workstations, where you can rely on the machinery for accuracy and force, hand tool woodworking relies heavily on precision, control, and the woodworker’s physical effort. A sturdy bench gives you the stability needed to work with hand planes, chisels, saws, and other tools. It also serves as an anchor for clamps and vises, enabling more accurate work. Essentially, the bench is your woodworking foundation, making it a must-have for any hand tool enthusiast.

Choosing the Right Workbench

- Size matters:

When selecting your first hand tool woodworking bench, the size of the bench is critical. You don’t need a massive table, but it should be large enough to comfortably work on various projects. A typical size for beginners is around 5 to 7 feet in length and 2 feet in width. The height is also important. A bench that’s too tall or too short can cause strain on your back and arms. Generally, a height between 30 and 36 inches works well, but the perfect height depends on your personal comfort and working style. - Material choice:

A good woodworking bench is made from solid, durable hardwood like maple, beech, or oak. These materials are dense and can withstand heavy use. A solid top is important for absorbing the impact of chisels and mallets without too much bounce or movement. The bench should be sturdy enough to stay in place even when applying a lot of pressure to your tools. - Stability is key:

One of the most essential features of a woodworking bench is stability. You’ll be applying significant force when sawing, planing, and chiseling, so it’s important that the bench doesn’t wobble. Many ready-made benches come with adjustable feet to ensure they sit level on uneven floors. If you’re building your own, make sure the legs are solid and secure.

Must-Have Features for Your Bench

- A built-in vise:

One of the most important features of a hand tool woodworking bench is a built-in vise. A vise helps secure your workpiece while you cut, plane, or chisel. For beginners, a front vise is typically enough to hold wood horizontally or vertically. A good vise should be easy to open and close and hold the wood firmly without damaging it. - Dog holes and bench dogs:

Dog holes are drilled into the surface of your bench and are designed to hold bench dogs, which are small pieces of metal or wood that help clamp your project in place. These are especially useful when planing long boards. You can position your project between the vise and the bench dogs to hold it securely while you work. Having a series of dog holes across your bench allows for more flexibility when clamping down various sizes of workpieces. - A solid work surface:

A thick, solid wood surface is a must for hand tool woodworking. The top should be thick enough to withstand pounding, chiseling, and planing without giving way. A thickness of at least 2 to 3 inches is recommended. A smooth, flat surface is also important to ensure your pieces stay level during assembly.

Organizing Your Hand Tools Around the Bench

- Pegboards and wall-mounted storage:

Keep your essential hand tools close at hand by organizing them around your workbench. A pegboard mounted above your bench is a great way to store commonly used tools like hammers, saws, and chisels. This keeps your workspace tidy and allows you to grab the tools you need without interrupting your workflow. You can also use magnetic strips for metal tools like chisels and screwdrivers. - Tool trays and drawers:

Consider adding tool trays or drawers underneath your bench. These are perfect for storing small items like screws, nails, and measuring tapes. They also provide a place to store hand planes and other delicate tools that shouldn’t be left out on the bench. You can build custom drawers or trays to fit the exact dimensions of your bench, ensuring that everything has a place. - Clamping solutions:

Clamps are essential in hand tool woodworking, and having them easily accessible is key. Install a clamp rack on the side of your bench, or use hooks to hang them underneath. Keeping clamps within arm’s reach will save you time and make your projects go more smoothly.

Adding a Bench Hook and Shooting Board

- Bench hook for cutting precision:

A bench hook is a simple but invaluable accessory for your woodworking bench. It’s a small wooden device that hooks onto the edge of your bench and holds your workpiece in place while you cut. This helps to keep your cuts straight and accurate, especially when using hand saws. A bench hook is easy to make yourself and can be customized to fit your specific needs. - Shooting board for planing edges:

A shooting board is another essential tool for hand tool woodworkers. It helps you plane perfectly straight or angled edges. The shooting board acts as a guide, allowing your hand plane to shave off small amounts of wood with precision. This is especially useful for creating square edges on boards or perfect miters for picture frames or boxes.

Lighting and Comfort Considerations

- Good lighting is essential:

Working with hand tools requires a lot of precision, and good lighting is critical for spotting fine details. Position your bench near a window for natural light during the day. For evening work or low-light conditions, install adjustable task lighting above your bench. LED lights are a great choice as they provide bright, clear light without creating too much heat. - Ergonomics and comfort:

Hand tool woodworking can be physically demanding, so it’s important to make your workspace as comfortable as possible. Choose a bench height that allows you to work without bending over too much. You may also want to invest in anti-fatigue mats to place in front of your bench, especially if you’ll be standing for long periods.

Maintaining Your Bench

- Keep the surface clean:

Wood shavings and dust will quickly accumulate on your bench, so it’s important to clean the surface regularly. A simple sweep with a brush after each project will keep your bench in good shape and make your next project easier. You can also use a vacuum or dust collection system to help with clean-up. - Regular oiling and conditioning:

If your bench is made from solid wood, it’s important to protect it from wear and tear. Regularly oiling the surface with linseed oil or another wood conditioner will help prevent cracks, scratches, and moisture damage. Apply a thin coat and allow it to soak in, then buff the surface with a clean cloth. - Inspect for damage:

Over time, your bench may develop nicks or dents from heavy use. Inspect it regularly and sand down any rough spots to keep the surface smooth. If a part of the bench becomes damaged or unstable, repair it right away to avoid any interruptions in your work.

Conclusion: Ready to Build Your Hand Tool Woodworking Bench?

Setting up your first hand tool woodworking bench doesn’t have to be a daunting task. With the right materials, features, and organization, you can create a bench that will serve you well for years to come. Remember, your bench is the foundation of your woodworking projects, so it’s worth taking the time to build it right. Whether you’re cutting dovetails or planing rough boards, a solid, well-organized bench will make all the difference. Ready to get started? Gather your materials and start building your dream hand tool woodworking bench today!