How to Save Money on CNC Woodworking Tools

Introduction

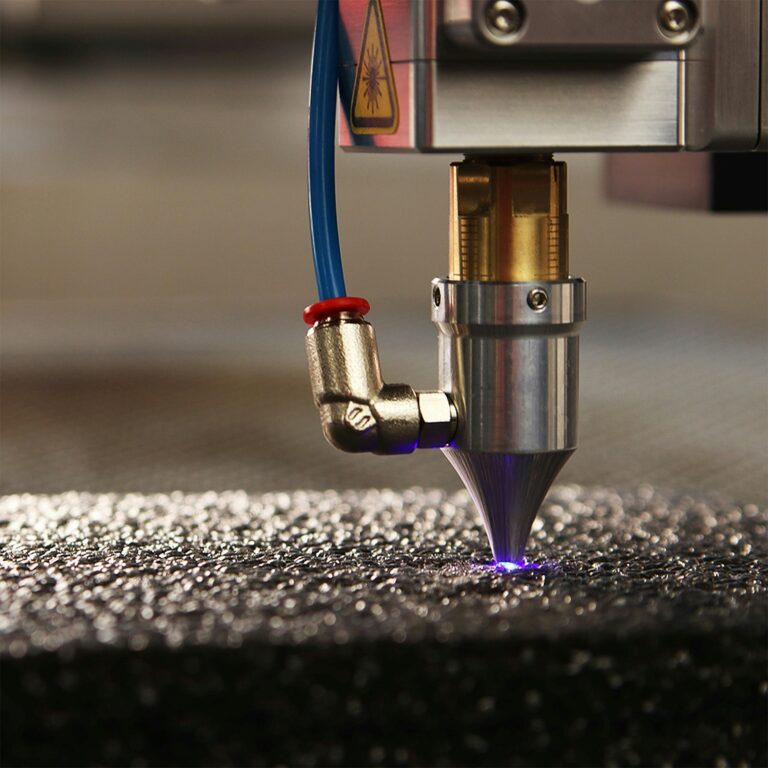

CNC woodworking is an exciting and rewarding hobby or business, but the costs can quickly add up if you’re not careful. From machines to bits, tools, and accessories, it’s easy to overspend. But don’t worry—there are plenty of ways to save money on CNC woodworking tools without compromising on quality. In this post, we’ll explore practical strategies to help you cut costs and maximize your budget so you can enjoy CNC woodworking without breaking the bank.

Buy Used CNC Machines and Tools

- Look for Gently Used CNC Machines

Buying a brand-new CNC machine can be a big investment, especially for beginners. Many woodworking enthusiasts and businesses upgrade their equipment regularly, leaving plenty of high-quality, used CNC machines available for sale. Look for gently used machines on marketplaces like Craigslist, Facebook Marketplace, or specialized woodworking forums. - Inspect the Condition Carefully

When purchasing used equipment, always inspect the machine carefully for signs of wear and tear. Pay close attention to the spindle, belts, and overall frame condition. Ask the seller for a demonstration if possible to ensure everything is working properly. - Buy Refurbished Tools from Reputable Sellers

Some companies specialize in refurbishing CNC machines and tools. These refurbished units come with warranties and quality checks, offering you peace of mind at a lower cost than brand-new equipment. - Check Online Auctions for Deals

Online auctions can be a goldmine for finding CNC tools at discounted prices. Websites like eBay often feature auctions for CNC accessories, bits, and even machines. Set a budget and keep an eye on auctions to snag a deal. - Negotiate with Sellers

Don’t be afraid to negotiate when buying second-hand tools. Many sellers are willing to offer a lower price, especially if the equipment has been listed for a while. Polite bargaining can help you save even more money.

Buy in Bulk to Save on Bits and Accessories

- Stock Up on Router Bits

Router bits are essential for CNC woodworking, and buying them one at a time can quickly become expensive. Many suppliers offer discounts if you buy bits in bulk, so consider purchasing a set of commonly used bits to save money over time. - Find Discounted Bit Sets

Some online retailers offer bit sets at discounted prices, which include multiple types of bits in various sizes. These sets are ideal for beginners, providing all the essentials at a lower cost than buying bits individually. - Bulk Buy Sandpaper and Finishing Supplies

Items like sandpaper, wood finish, and sealant are used frequently in CNC woodworking, and buying these supplies in bulk can significantly reduce your costs. Look for discounts at hardware stores or online when purchasing large quantities. - Group Purchases with Other Woodworkers

If you’re part of a local woodworking community, consider pooling your resources and making group purchases of bits, wood, or accessories. Bulk purchases often come with significant discounts, and splitting the cost with other woodworkers can help everyone save money. - Check for Sales and Discounts on CNC Accessories

Keep an eye out for sales on CNC accessories like clamps, dust collection systems, and router tables. Many retailers offer discounts during holidays or special promotions, so be patient and purchase these items when they go on sale.

Use Free or Low-Cost CNC Software

- Start with Free Software

Many beginner-friendly CNC software options are available for free, such as Easel and Carbide Create. These programs offer all the basic features you need to design and run projects without requiring a financial investment upfront. - Take Advantage of Free Trials

More advanced CNC software, such as VCarve Pro and Fusion 360, offer free trials that allow you to test the software before committing to a purchase. Make the most of these free trials to see if the software fits your needs without spending money immediately. - Use Open-Source Alternatives

Open-source software like Inkscape and FreeCAD are great alternatives to paid CNC design programs. While they may lack some advanced features, they’re powerful enough for most beginner to intermediate projects and won’t cost you a dime. - Look for Discounted Software Licenses

Many CNC software companies offer discounted licenses for students, hobbyists, or small businesses. If you fall into one of these categories, take advantage of these discounts to save on software costs. - Watch for Software Sales

Software companies frequently offer discounts during major sales events like Black Friday, Cyber Monday, or New Year’s sales. If you’ve been eyeing a specific software, wait for these sales to purchase it at a lower price.

Repurpose and Reuse Materials

- Use Scrap Wood for Practice Projects

If you’re just starting out, use scrap wood or leftover materials from other projects to practice your CNC skills. Scrap wood is often available for free or at a low cost and is perfect for test cuts or practice designs. - Salvage Materials from Old Furniture

Repurposing old furniture or reclaimed wood can be a cost-effective way to source materials for CNC projects. You can find old furniture at thrift stores or even on the curb during neighborhood clean-up days, providing you with plenty of wood to work with for free or cheap. - Use Off-Cuts from Larger Projects

Off-cuts from larger projects can be repurposed for smaller CNC projects like coasters, plaques, or ornaments. Instead of discarding these leftover pieces, save them for future use to maximize your materials. - Recycle Materials for Creative Projects

Get creative by using recycled or upcycled materials in your CNC projects. Pallets, wooden crates, or even plastic can be repurposed for unique woodworking designs. Not only does this save you money, but it also promotes sustainability. - Check Local Wood Suppliers for Discarded Materials

Many lumberyards or woodworking suppliers discard materials that are slightly imperfect or smaller than standard sizes. Ask around at local suppliers to see if they have any leftover wood that they’re willing to give away or sell at a discount.

Maintain Your Tools to Extend Their Lifespan

- Sharpen Router Bits Regularly

Dull bits can lead to rough cuts and put extra strain on your CNC machine, potentially leading to damage. Regularly sharpening your bits will not only improve the quality of your projects but also save you money by extending the life of your tools. - Lubricate Moving Parts

Keeping your CNC machine’s moving parts well-lubricated ensures smooth operation and prevents wear and tear. Regular maintenance will help avoid costly repairs and keep your machine in top condition. - Clean Your Machine After Each Use

Dust and debris can accumulate in your CNC machine over time, leading to reduced performance or breakdowns. Regular cleaning after each use will help prevent these issues and keep your machine running smoothly. - Replace Worn Parts Before They Break

Don’t wait until parts of your CNC machine break before replacing them. Regularly inspect belts, bearings, and motors for signs of wear, and replace them as needed to avoid more expensive repairs down the line. - Follow the Manufacturer’s Maintenance Guidelines

Each CNC machine comes with specific maintenance guidelines provided by the manufacturer. Following these guidelines closely will help ensure that your machine remains in excellent working condition for years to come.

Conclusion

CNC woodworking doesn’t have to be expensive. By buying used equipment, taking advantage of free software, and practicing smart maintenance, you can significantly reduce costs while still creating high-quality projects. These money-saving tips will help you make the most of your budget, allowing you to enjoy CNC woodworking without overspending.