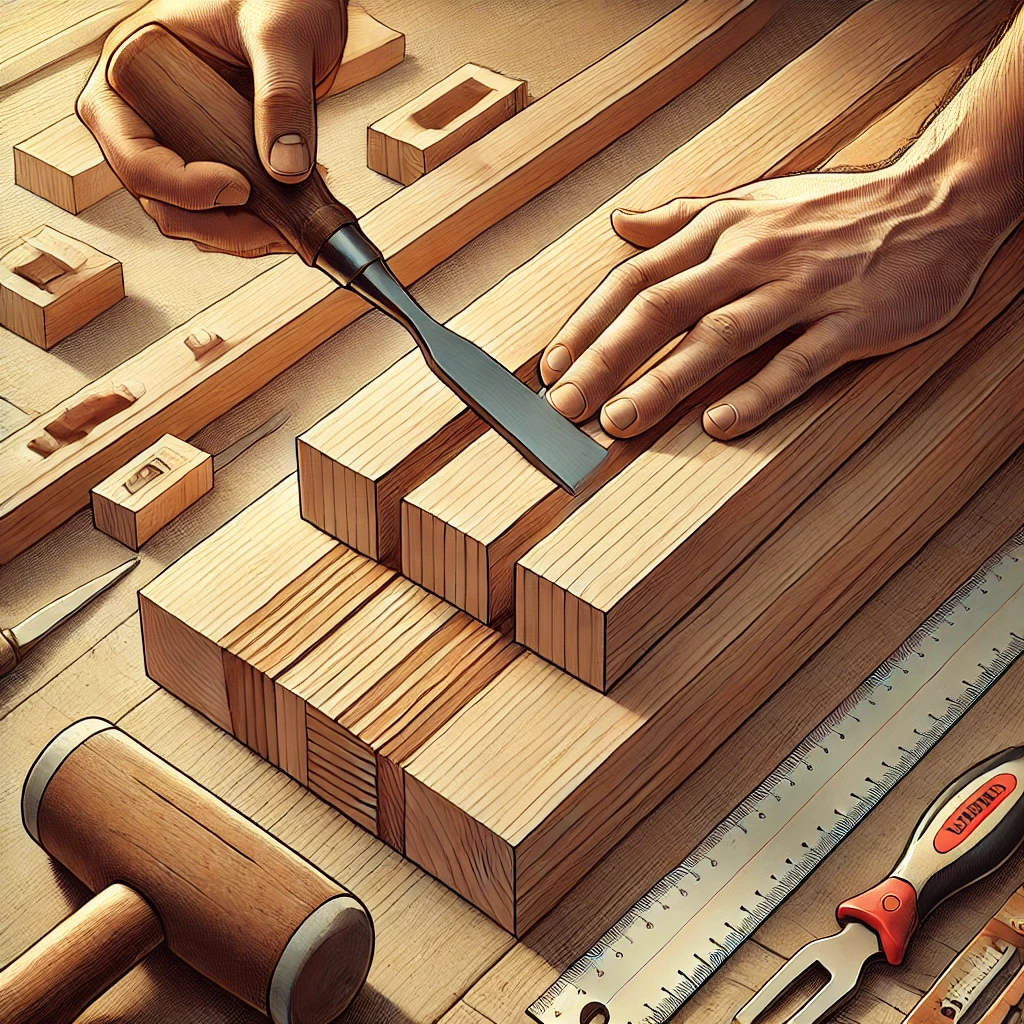

How to Use a Chisel for Perfect Mortise and Tenon Joints

Introduction

- The mortise and tenon joint is one of the most traditional and durable joints in woodworking, essential for building furniture and structures that stand the test of time. It’s a skill every woodworker should master. Using chisels correctly to create these joints ensures a precise fit, which is critical for both the joint’s strength and the overall aesthetic of your project. In this guide, we will walk you through the necessary chisel techniques to produce flawless mortise and tenon joints, along with step-by-step instructions that will turn any beginner into a master woodworker.

What is a Mortise and Tenon Joint?

- Understanding the Mortise and Tenon Joint: The mortise and tenon joint is a centuries-old woodworking technique used to join two pieces of wood, usually at a 90-degree angle. The tenon, which is a protruding section at the end of one piece, fits snugly into the mortise, a cavity in the other piece of wood. The joint can be glued, pegged, or wedged to increase its strength. This joint is widely recognized for its ability to hold substantial weight and endure stress, making it ideal for chairs, tables, and timber frames. Knowing how to create a precise mortise and tenon joint enhances both the structural integrity and beauty of your woodworking project. We will explore how to achieve this using chisels, focusing on proper techniques to ensure accuracy.

Tools You’ll Need for Creating Mortise and Tenon Joints

- Choosing the Right Chisels: Not all chisels are created equal, especially when it comes to creating mortise and tenon joints. Mortise chisels, in particular, are designed to remove large amounts of wood and withstand the force required for this task. These chisels have thick, sturdy blades that allow for deep, clean cuts without chipping or bending. In addition to mortise chisels, bench chisels can be used for finer detail work, like cleaning up the edges of the joint. Sharpness is key when using chisels, as dull blades can lead to inaccurate cuts and an uneven joint. Beyond the chisels, you will also need a mallet for driving the chisel, a marking gauge for outlining the joint, and possibly a coping saw for cutting the tenon.

Step-by-Step Guide to Chiseling the Mortise

- Step 1: Marking the Mortise: Before making any cuts, it is crucial to accurately mark the location and size of the mortise. A marking gauge is invaluable for this step, ensuring straight and parallel lines. You can also use a square to ensure your layout is precise. The size of the mortise should typically be one-third the thickness of the wood. Once marked, use a sharp pencil or knife to define the edges of the mortise to prevent the wood from tearing during chiseling. Taking the time to set up correctly will save you from mistakes down the line, as precision in this step leads to better-fitting joints.

- Step 2: Chiseling Out the Waste: With your mortise accurately marked, the next step is to begin removing the waste. Start by placing the chisel at the center of the mortise and tapping it with a mallet. The key here is to remove small amounts of wood at a time, working slowly and methodically toward the edges. Chiseling too much at once can cause the wood to split or lead to an uneven mortise. Work from both ends of the mortise towards the center, keeping the chisel perpendicular to the wood. This approach will give you a clean cut and a well-defined mortise. After the majority of the wood is removed, use finer chisels to clean up the edges and ensure the mortise is smooth and ready for the tenon.

Step-by-Step Guide to Creating the Tenon

- Step 1: Sizing the Tenon: The tenon should be sized to match the mortise precisely. Use a marking gauge to scribe lines on all four sides of the tenon. The tenon should be slightly smaller than the mortise to allow for a snug fit. Once the lines are marked, you can use a saw to cut along these lines, stopping just short of the base of the tenon. Accuracy is key here, as any deviation can cause the tenon to be too loose or too tight. A tenon that’s too loose will result in a weak joint, while one that’s too tight can cause the wood to split during assembly.

- Step 2: Fine-Tuning the Fit with a Chisel: After the tenon has been cut, use a chisel to fine-tune its shape. Remove small amounts of material at a time, focusing on creating smooth, even surfaces. Check the fit often by attempting to insert the tenon into the mortise. The goal is to achieve a snug fit that requires a little pressure to insert but does not force the wood apart. If necessary, use sandpaper or a file to smooth out any rough areas. The tenon should fit flush with the surface of the mortise without gaps, ensuring the joint is both strong and aesthetically pleasing.

Conclusion

- Crafting a perfect mortise and tenon joint requires precision and practice, but the results are well worth the effort. By following the steps outlined above and using the right chisels, you can create strong, durable joints that will last for years. Remember, patience and accuracy are key—rushing through the process can lead to mistakes that compromise the strength of your joint. With practice, these techniques will become second nature, and your woodworking projects will benefit from the strength and beauty of well-crafted joints. So, grab your chisels and start honing your skills today!