How to Get Started with CNC Woodworking A Complete Guide for 2024!

Introduction

Are you ready to create stunning wood designs with a CNC machine but don’t know where to start? This guide will help you kick off your CNC woodworking journey with confidence. Let’s walk through the essential steps of setting up your CNC workspace, understanding the tools, and running your first project.

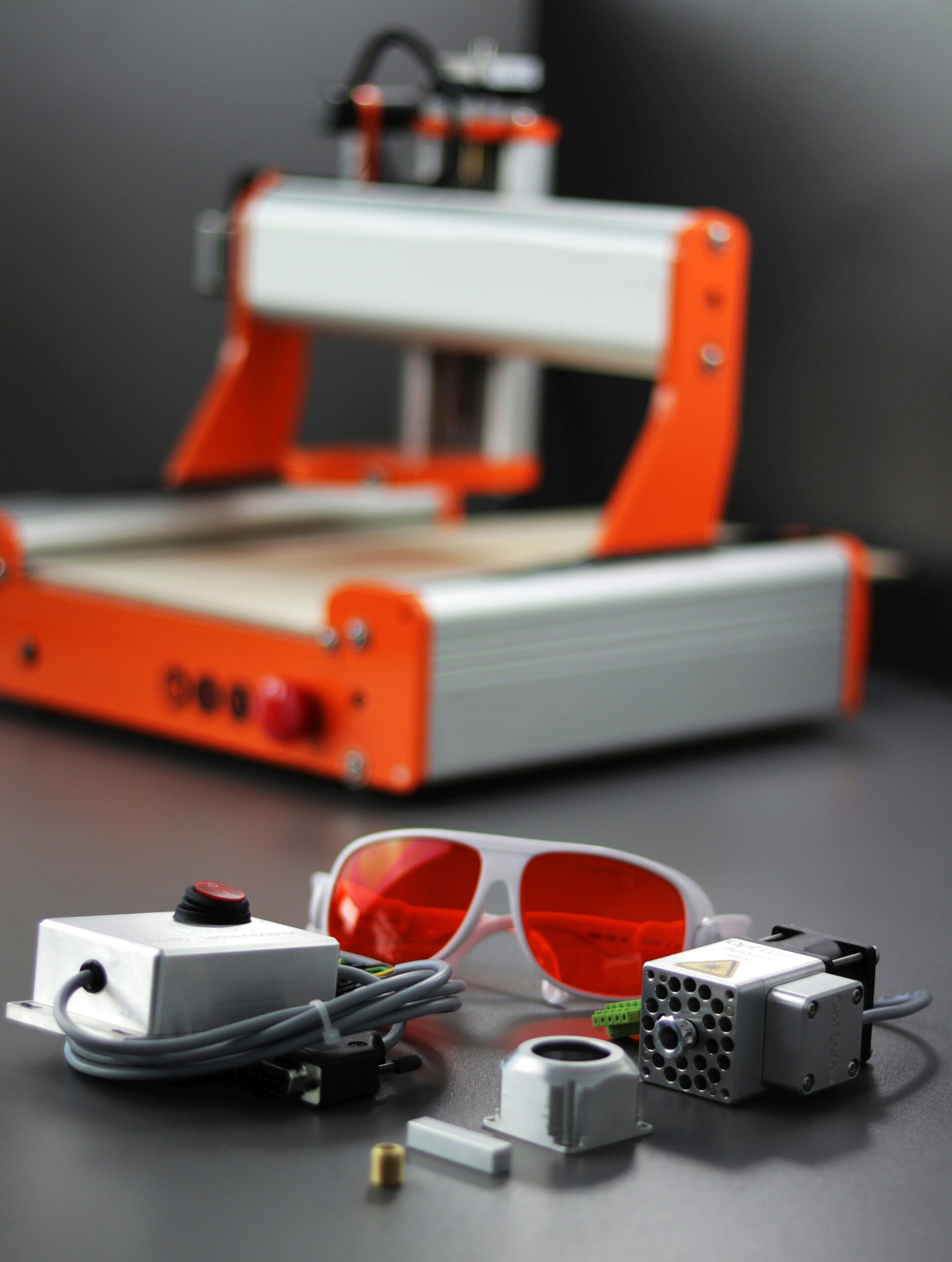

Choose the Right CNC Machine for Beginners

- Budget-Friendly Options

When starting out, it’s important to choose a CNC machine that fits your budget but still offers good quality. Machines like the Shapeoko 4, Genmitsu 3018-PRO, and BobsCNC Evolution 4 are all affordable options that are beginner-friendly while still delivering precise results. - Router vs. Mill

A router is the most common type of CNC machine used for woodworking, while a mill is typically used for metal. For beginners, a CNC router is the best option as it’s easier to operate and more versatile for various wood projects. - Machine Size

The size of the CNC machine will depend on the projects you plan to work on. If you’re only making small items, a compact machine like the Genmitsu 3018-PRO will be sufficient. However, if you’re aiming for larger furniture pieces, you’ll need a larger machine like the Shapeoko. - Assembly and Setup

Some CNC machines come pre-assembled, while others require some setup. For beginners, it’s best to choose a machine with easy-to-follow assembly instructions, like BobsCNC Evolution 4, which offers online support and tutorials for first-time users. - Software Compatibility

Before purchasing a CNC machine, ensure that it’s compatible with popular design software like Fusion 360, Easel, or VCarve Pro. Many beginner-friendly CNC machines come with bundled software, which makes the learning process smoother.

Setting Up Your CNC Workspace

- Dedicated Workspace

A CNC machine requires a fair amount of space, so it’s important to set up a dedicated area for your woodworking projects. Ensure that the space is well-ventilated, clean, and has enough room for the machine to move freely without obstruction. - Stable Work Surface

The CNC machine should be placed on a sturdy and flat workbench. This ensures that the machine doesn’t wobble or move during the cutting process, which could affect the precision of the cuts. Consider adding rubber feet or a vibration-dampening mat underneath the machine for extra stability. - Power Supply

CNC machines require a reliable power source. Make sure your workspace has easy access to an electrical outlet and that the wiring can handle the power requirements of your machine. For larger machines, it may be necessary to install dedicated power lines. - Lighting

Adequate lighting is crucial for CNC woodworking. Since you’ll need to monitor the cutting process and ensure accuracy, setting up overhead or task lighting directly above the machine will help you keep an eye on your work. - Storage for Tools and Materials

Keep your CNC tools, router bits, and wood materials organized by adding shelves or cabinets to your workspace. Having everything within reach will make the workflow more efficient and reduce the chances of misplacing important items.

Learning CNC Design Software

- Starting with Beginner-Friendly Software

For those new to CNC woodworking, software like Easel or Carbide Create is perfect for beginners. These programs have simple user interfaces, making it easy to create your first designs without feeling overwhelmed by complex features. - Online Tutorials and Resources

Many design software platforms offer tutorials and user guides to help you get started. Fusion 360, for instance, provides step-by-step video tutorials on creating designs and operating CNC machines, ensuring that you get up to speed quickly. - Practicing with Free Templates

A great way to get familiar with CNC software is to use free templates. Many software programs have pre-made designs that you can import and modify. This gives you the opportunity to practice without having to start from scratch. - Creating Your Own Designs

Once you feel comfortable, start experimenting with your own designs. Begin with simple shapes and patterns, and gradually work your way up to more intricate projects. Many beginners find it rewarding to see their designs come to life in wood. - Troubleshooting Common Design Errors

When learning CNC software, you might encounter errors like incorrect scaling or toolpath problems. It’s important to troubleshoot these issues early on, and most software offers error-checking features to help identify and correct mistakes before you start cutting.

Running Your First CNC Project

- Choosing a Simple Project

Start with a basic project like engraving a simple nameplate or cutting out a basic shape. This will allow you to get familiar with the machine’s operation without feeling overwhelmed by complexity. - Setting Up the Material

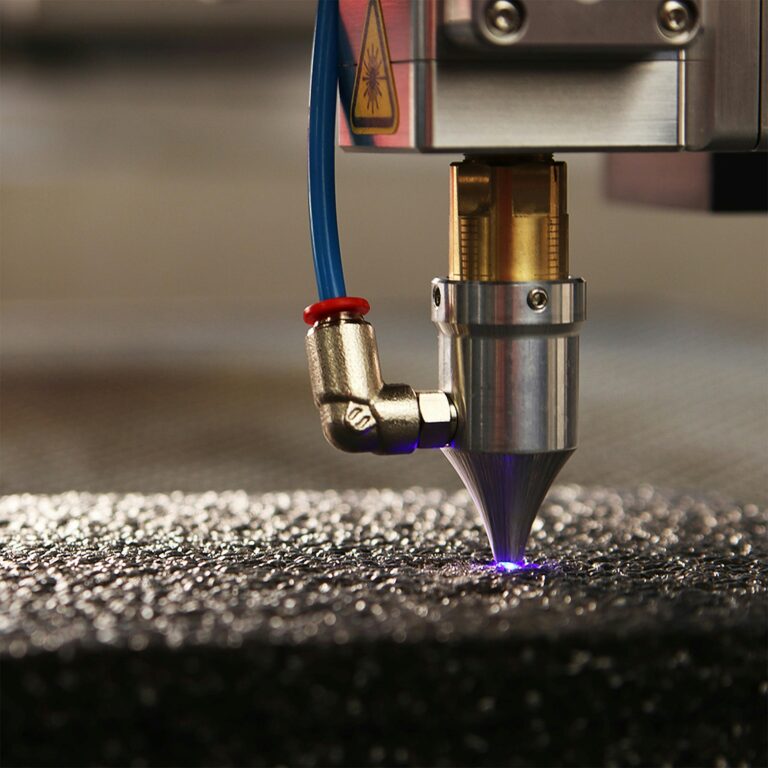

Secure your wood material to the CNC table using clamps or fixtures. Ensure that the material is flat and properly aligned with the router bit to avoid errors in the cuts. Double-check all settings before starting. - Running a Test Cut

Before beginning the full project, it’s a good idea to run a test cut on a scrap piece of wood. This ensures that the machine is calibrated correctly, and the design will be cut as expected. If the test cut reveals any issues, make adjustments before proceeding. - Monitoring the Cutting Process

Keep an eye on the machine while it’s running. Although CNC machines are automated, they can still encounter problems like material shifting or bit breakage. Being present allows you to stop the machine if something goes wrong. - Finishing Your Project

Once the machine has completed the cuts, remove the material from the table and inspect it for accuracy. If necessary, sand down rough edges and apply any finishing touches, such as staining or sealing the wood.

Conclusion

Getting started with CNC woodworking is an exciting journey. With the right machine, tools, and knowledge of the software, you’ll soon be creating stunning designs with precision and ease. Whether you’re a hobbyist or looking to turn this into a business, CNC woodworking opens up a world of creative possibilities.