CNC Woodworking How to: A Beginner’s Introduction

CNC woodworking is revolutionizing the way we approach woodcraft. With a CNC (Computer Numerical Control) machine, even beginners can create precise and detailed projects. In this post, we’ll introduce you to CNC woodworking, explain what it is, and show you how it works.

CNC Woodworking Defined

- Computer Numerical Control (CNC):

CNC stands for Computer Numerical Control, a process where computers control machine tools. This method allows for highly accurate movements and precision that is hard to achieve manually. CNC woodworking uses this technology to cut, shape, and design wooden pieces based on a pre-programmed set of instructions. - Automation in Woodworking:

One of the biggest advantages of CNC woodworking is automation. Once the design and settings are input into the machine, the CNC router can automatically complete the project with minimal human interference, ensuring accuracy and reducing error. - Precision and Repeatability:

CNC woodworking is known for its high level of precision. It allows for consistent repeatability, meaning you can produce identical pieces over and over without any variation. This is particularly useful for businesses producing furniture or decorative items in bulk. - 3D Capabilities:

CNC machines can carve not just flat designs but also intricate 3D shapes, which opens up endless creative possibilities. This makes them popular for detailed woodworking, from simple engravings to complex sculptures. - Versatility in Materials:

While CNC woodworking machines are primarily designed for wood, they are also capable of working with a variety of other materials, including plastics, metals, and composites. This versatility allows users to experiment with different materials and expand their creative possibilities.

Why CNC Woodworking is Perfect for Beginners

- Ease of Learning:

CNC machines are highly accessible even to those with little woodworking experience. Many CNC routers come with user-friendly software that includes beginner-friendly tutorials and guidance, making the learning curve manageable for first-timers. - Minimal Manual Labor:

Unlike traditional woodworking, which requires substantial physical effort, CNC woodworking is mostly automated. Once the machine is set up and calibrated, the CNC router handles the cutting and carving, making it less labor-intensive. - Improved Accuracy and Quality:

Beginners can often struggle with precision in manual woodworking. CNC machines eliminate this challenge by providing a high level of accuracy and reducing the risk of human error. This helps beginners produce high-quality results right from the start. - Project Variety:

CNC woodworking allows beginners to work on a wide variety of projects, from simple designs like wooden coasters to more complex furniture. The versatility of CNC machines enables beginners to progress at their own pace and tackle more ambitious projects as they gain confidence. - Affordable Entry Points:

CNC machines range in price, but there are many affordable options for beginners. Brands like Shapeoko and BobsCNC offer entry-level machines that deliver professional-quality results without breaking the bank.

Tools You’ll Need for CNC Woodworking

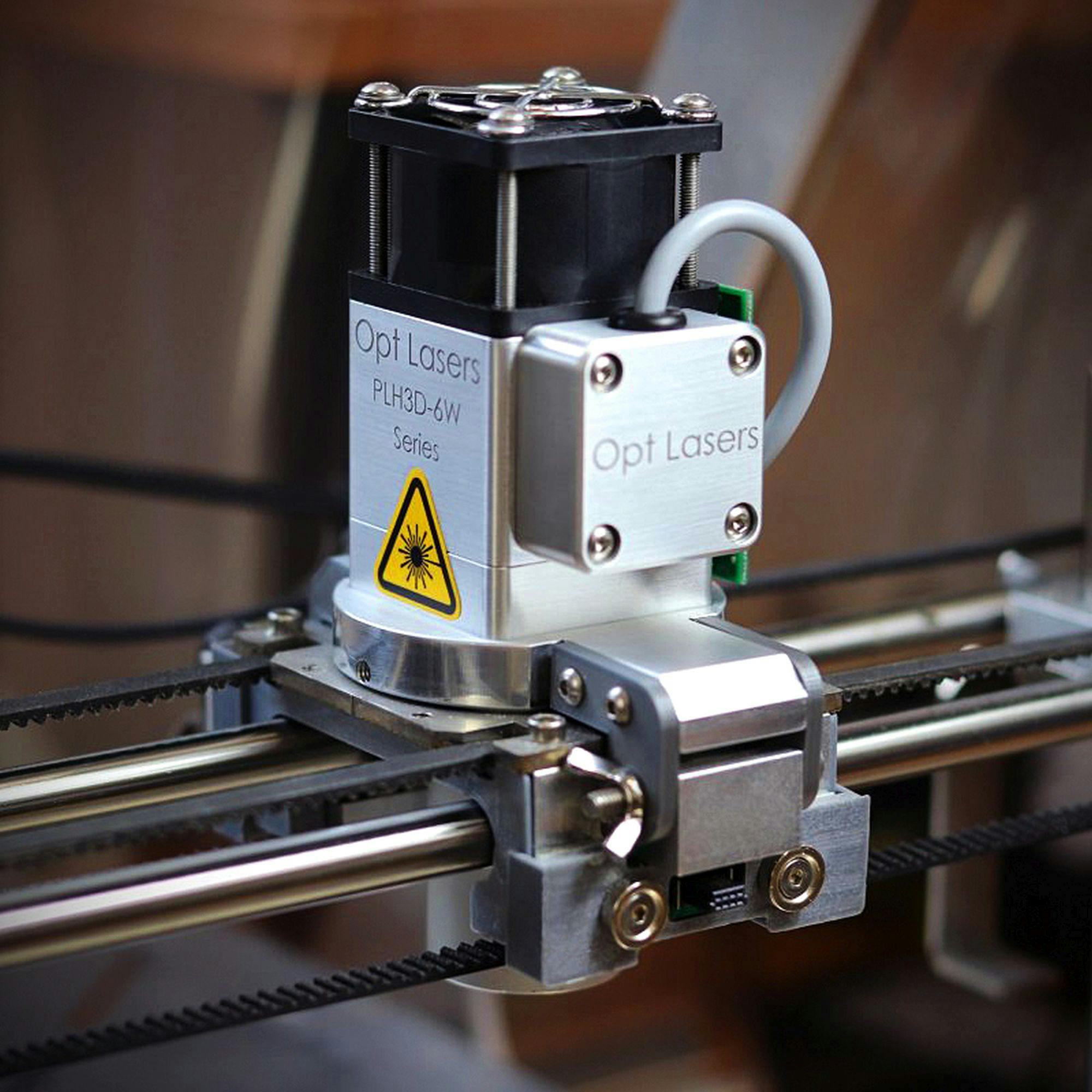

- CNC Router:

The CNC router is the main tool in any CNC woodworking setup. It is responsible for cutting, carving, and shaping the wood according to the instructions provided by the computer. For beginners, it’s important to choose a router that is easy to set up and reliable, such as the X-Carve or Genmitsu. - Design Software:

Software is crucial in CNC woodworking, as it’s where the design process begins. Programs like Fusion 360, Easel, and VCarve Pro allow users to create or import designs that the CNC machine will follow. Many of these programs offer free trials or low-cost versions for beginners to practice on. - Router Bits:

The router bit is the part of the CNC machine that actually makes contact with the wood. Different bits serve different purposes: some are used for fine detail work, while others are better for cutting through thicker materials. Beginners should start with a basic set of bits that cover a range of cuts, from engraving to cutting. - Dust Collection System:

CNC woodworking can create a lot of dust and debris, which can interfere with the machine’s operation and affect the quality of the project. A dust collection system helps keep the workspace clean and prolongs the life of the CNC machine by preventing dust from getting into sensitive components. - Clamps and Fixtures:

To ensure the material stays in place during the cutting process, clamps and fixtures are essential. They hold the wood securely to the CNC table, reducing movement and ensuring that the cuts are accurate. Beginners should invest in a set of clamps to prevent any mishaps during their first projects.

Conclusion:

Understanding CNC woodworking is the first step in becoming a successful woodworker. From the precision offered by the technology to the ease of learning, CNC woodworking makes intricate designs accessible to everyone, especially beginners. With the right tools and knowledge, you’ll be creating your own projects in no time. Now’s the time to dive into the world of CNC woodworking and unlock your potential.