Best Materials for 3D Printing: What You Need to Know

Introduction

Hey there! Welcome to the fascinating universe of 3D printing, where the only limit is your imagination—well, and maybe your printer’s build volume! Seriously though, it’s an exciting time to be alive when you can dream up a design and watch it come to life right in front of your eyes. It’s like magic, but with more plastic involved.

Now, let's chat about something crucial in this whole process: the materials. You see, choosing the right material is like picking the right pair of shoes for a hike. You wouldn't wear flip-flops to climb a mountain, right? The same goes for 3D printing. The material you choose can totally make or break your project. Whether you're crafting a cute little figurine or a part for your next DIY gadget, each material has its own personality, quirks, and best-use scenarios.

3D printing is gaining popularity faster than a cat video going viral. Everyone from hobbyists to big companies is jumping on the bandwagon, and for a good reason! But before you get too carried away with ideas, it's essential to understand the foundation of your masterpiece: the materials. So, buckle up, and let's embark on this journey to discover the best materials for your next 3D printing adventure. Who knows? You might find your new favorite material to work with!

Understanding 3D Printing Materials

Alright, buckle up! We're about to dive into the colorful and sometimes confusing world of 3D printing materials. Think of them like the ingredients in your grandma's famous chocolate chip cookies. Just as the right combination can lead to deliciousness, the right 3D printing material can make your project truly shine.

So, what exactly are these materials? In the simplest terms, they are the medium that your 3D printer uses to transform digital designs into physical objects. They come in many forms, like filaments, powders, and resins, each with its own personality and quirks. These materials are the unsung heroes, working tirelessly behind the scenes to bring your creations to life.

Now, choosing the right material is like picking the perfect outfit for a party. You wouldn't wear a swimsuit to a black-tie event, right? Similarly, you need to consider a few key factors when selecting your 3D printing material. First up, strength. If you're printing something that needs to hold its own, like a sturdy phone case or a tool, you'll want a material that can take a beating. On the other hand, if you're crafting something more delicate, like a piece of jewelry, flexibility might be more important.

Then there's cost. Ah, yes, the ever-present budget. Some materials are as cheap as chips, while others might have you contemplating taking out a second mortgage. It's all about finding that sweet spot where quality meets affordability. And let's not forget about availability. Some exotic materials might sound tempting, but if you can't get your hands on them, they're about as useful as a chocolate teapot.

Finally, think about your printer's capabilities. Not all printers can handle every material, so it's crucial to know what your trusty machine can manage before you start dreaming big. After all, you wouldn't want to put diesel in a car that runs on regular gas, would you?

So there you have it! A quick tour of the things to keep in mind when picking your 3D printing material. With these insights up your sleeve, you're well on your way to becoming a 3D printing maestro. Happy printing!

The Best 3D Printing Materials

Alright, folks, let's dive into the nitty-gritty of 3D printing materials. It's like choosing the right tool for the job. You wouldn't use a spoon to hammer a nail, right? The material you pick can drastically affect the outcome of your project, so let's break it down.

PLA (Polylactic Acid)

First up, we have PLA, the darling of the 3D printing world. Why? Because it's like the friendly neighbor of materials—easy to work with and always ready to lend a hand. PLA is biodegradable, which means it’s not only good for your projects but also for the environment. It's great for beginners due to its low printing temperature and minimal warping. You’ll often find it used in toys, prototypes, and models. If you want something simple and eco-friendly, PLA is your go-to.

ABS (Acrylonitrile Butadiene Styrene)

Now, if PLA is the friendly neighbor, ABS is the tough, no-nonsense friend who gets things done. Known for its strength and durability, ABS is like the bodybuilder of 3D printing materials. It's perfect for industrial parts and functional components. However, it does have a temper—it requires a heated bed and can be a bit smelly while printing. But if you need something robust, ABS is your guy.

PETG (Polyethylene Terephthalate Glycol)

Enter PETG, the superhero material that balances flexibility and strength. It's like the Swiss Army knife of 3D printing materials. PETG is resistant to moisture and chemicals, making it ideal for outdoor projects or anything that needs to withstand the elements. It’s great for making water bottles, mechanical parts, and even protective gear. If versatility is what you’re after, PETG has got your back.

Nylon

Nylon is the powerhouse of versatility. Imagine it as the multitasker in your office who can handle any project thrown their way. It's tough, durable, and has a bit of flexibility, making it a favorite for engineering and mechanical parts. Need to print a gear or a hinge? Nylon's tensile strength is perfect for those heavy-duty jobs. Just remember, it can be a bit finicky with moisture, so keep it dry!

TPU (Thermoplastic Polyurethane)

TPU is the fun, flexible friend you never knew you needed. Think of it as the rubber band of 3D printing materials. It’s stretchy, bendy, and can take a beating, making it ideal for creating things like phone cases, shoe soles, or any object that needs to absorb impact. If you want to add a bit of bounce to your creations, TPU is definitely worth a try.

Resin

Last but not least, let's talk about resin. If you’re looking for high detail and a smooth finish, resin is your material. It's like the artist of the group, perfect for intricate models and detailed prototypes. However, it does require a bit more care and post-processing. But for that stunning detail, it’s totally worth it. Just think of it as the Michelangelo of 3D printing materials.

So there you have it, a rundown of the best materials for 3D printing. Whether you’re looking for strength, flexibility, or detail, there’s a material out there that’s perfect for your project. Happy printing!

PLA (Polylactic Acid)

Ah, PLA. If 3D printing materials had a popularity contest, PLA would probably be the prom king (or queen)! This material is like the friendly neighbor of the 3D printing world—approachable, reliable, and always ready to lend a hand. Let’s break down why it’s such a crowd favorite.

First off, PLA is known for its ease of use. If you’re just dipping your toes into 3D printing, PLA is your go-to. It’s like the training wheels of 3D printing materials. Why? Because it’s super forgiving. You don’t need a fancy printer with a heated bed to make it work, and it doesn’t warp like some of its more temperamental cousins. It’s kind of like the Goldilocks of materials—not too hot, not too cold, just right.

Now, let’s talk about biodegradability. PLA is made from renewable resources like corn starch or sugarcane. So, it’s not just easy to print with; it’s also easy on the planet. In a world where sustainability is more than just a buzzword, using PLA can give you a little eco-friendly pat on the back. It’s not going to save the world single-handedly, but every little bit helps, right?

So, what can you make with PLA? Well, the possibilities are pretty endless. Think of it as the Swiss army knife of 3D printing materials. You can create anything from simple toys and trinkets to intricate models and prototypes. It’s perfect for hobbyists who want to make cool stuff without breaking the bank. Plus, it comes in a rainbow of colors, so you can make your creations as vibrant as your imagination.

In summary, PLA is the best buddy you didn’t know you needed in your 3D printing journey. It’s easy to use, kind to the environment, and versatile enough to tackle a wide range of projects. So, if you’re looking for a material that’s as dependable as your morning coffee, PLA’s got your back!

ABS (Acrylonitrile Butadiene Styrene)

Alright, let's talk ABS, the superhero of 3D printing materials! If PLA is the friendly neighborhood Spider-Man of the 3D printing world, then ABS is definitely more like Iron Man—strong, durable, and ready to take on some serious challenges. It's the kind of material that can handle stress and still come out looking good. Why? Because ABS is known for its incredible strength and toughness. This stuff can take a beating, which makes it perfect for creating things that need to withstand a lot of wear and tear.

Now, if you’re thinking about using ABS, you're probably looking to make something that’s more than just a pretty face. ABS is ideal for functional parts, especially in industrial settings. Think of gears, automotive parts, or even those clicky mechanisms in your pen. It's the go-to for projects where durability is a must. Plus, ABS has a higher melting point, which means it can withstand higher temperatures without losing its shape. So, if you plan to leave your 3D printed masterpiece in a hot car, ABS will have your back!

However, it's not all sunshine and rainbows. ABS can be a bit finicky to print with. It tends to warp if the temperature isn’t just right, and it can release some not-so-friendly fumes. So, you'll want a well-ventilated area and maybe a printer with an enclosed build space. But hey, every superhero has a kryptonite, right?

In short, if you're ready to tackle a project that demands strength and durability, ABS is your material. Just be sure to suit up (with proper ventilation), and you'll be creating functional parts that are ready to save the day—or at least your project!

PETG (Polyethylene Terephthalate Glycol)

Alright, let's talk about PETG, or as I like to call it, the superhero of 3D printing materials. Why a superhero, you ask? Well, it has a pretty impressive set of powers! PETG strikes a fantastic balance between flexibility and strength, kind of like that friend who's both a yoga master and a weightlifting champ. It's the perfect middle ground for when you need something that's strong, but not too rigid.

One of the coolest things about PETG is its resistance to moisture and chemicals. Imagine making a water bottle or a food container that doesn't warp or degrade over time. That's PETG for you! It's like having a personal bodyguard for your prints, ensuring they withstand the elements and keep their integrity. So, if you're planning to create objects that might get wet or come into contact with harsh substances, PETG is your go-to material.

But let's not stop there. PETG is also pretty easy to work with. It doesn't warp as much as ABS, and it doesn't require a heated bed, which makes it a friendly choice for beginners and pros alike. Plus, it has a nice glossy finish that can make your projects look super sleek and professional. Whether you're printing functional parts, prototypes, or just cool stuff to impress your friends, PETG has got your back.

So, next time you're pondering over which material to choose for your project, remember PETG. It's like having a trusty sidekick in your 3D printing adventures, always ready to support your creative endeavors with its strength, flexibility, and resilience. Give it a try—you might just find your new favorite material!

Nylon

Ah, nylon! The unsung hero of 3D printing materials. If you're looking for something that's tough as nails and versatile enough to handle a range of applications, nylon might just be your new best friend. It's like the Swiss Army knife of 3D printing materials. Seriously. You could probably use it to print a Swiss Army knife, if you wanted!

Nylon is renowned for its toughness. We're talking serious strength here—perfect for engineering and mechanical parts that need to withstand a bit of a beating. It's not just about being strong, though. Nylon is also incredibly versatile. It can handle a variety of applications, from functional prototypes to end-use parts. If you're in the business of making parts that need to last, nylon is your go-to.

One of the coolest things about nylon is its ability to be both strong and flexible. It's like that friend who's always up for an adventure but can still chill on the couch when you need them to. This balance makes it ideal for creating parts that need to flex without breaking, like gears and hinges. Plus, it’s resistant to wear and tear, which means your printed parts will have a long life.

But wait, there's more! Nylon is also pretty good at absorbing impact, which is why it's often used in the automotive and aerospace industries. It’s like having a built-in shock absorber for your projects. And if you're into vibrant colors, you're in luck—nylon can be easily dyed, allowing for a splash of personality in your creations.

Now, a little heads-up: nylon can be a bit tricky to print with. It loves to absorb moisture from the air, which can mess with your print quality. So, keep it dry and store it properly, and you'll be golden. Trust me, it’s worth the extra effort.

In short, if you're after a material that offers durability, flexibility, and a bit of pizzazz, nylon should definitely be on your radar. It's the kind of material that makes you wonder why you didn't try it sooner. So go ahead, give nylon a shot and see how it can elevate your 3D printing game!

TPU (Thermoplastic Polyurethane)

Alright, let's talk about TPU! If you've ever wanted to print something that's a little more bouncy or flexible, this is the material for you. Imagine the kind of rubbery feel of a phone case or the squishiness of a stress ball—that’s TPU in action. It's a superstar when it comes to flexibility, making it perfect for projects where you need a bit of stretch.

One of the coolest things about TPU is its durability combined with flexibility. It's like having the best of both worlds. Need to print a phone case that can absorb drops or a pair of custom-fit insoles? TPU’s got your back. It’s impact-resistant, which means it can take a beating and still come out swinging. This makes it a favorite for printing objects that need to withstand some wear and tear.

But wait, there’s more! TPU isn't just about being flexible and tough. It’s also resistant to oils and grease, which can be super handy depending on what you're making. Picture this: a custom gasket for a kitchen appliance that can handle a bit of a spill. Or maybe some outdoor gear that can brave the elements without giving up. TPU's resistance to chemicals and moisture makes it a champ in these scenarios.

Now, let’s talk about printing with TPU. It’s not as easy as PLA, but it’s not rocket science either. You might need to tweak your printer settings a bit. Slower speeds and a direct drive extruder can make your life easier when working with this material. It’s a little finicky, but once you get the hang of it, the possibilities are endless.

In short, if your project needs to bend but not break, TPU is your go-to. It's like the yoga master of 3D printing materials—flexible, resilient, and ready to adapt to whatever you throw at it. So, go ahead and experiment with TPU. You might just find it’s the perfect fit for your next unique creation!

Resin

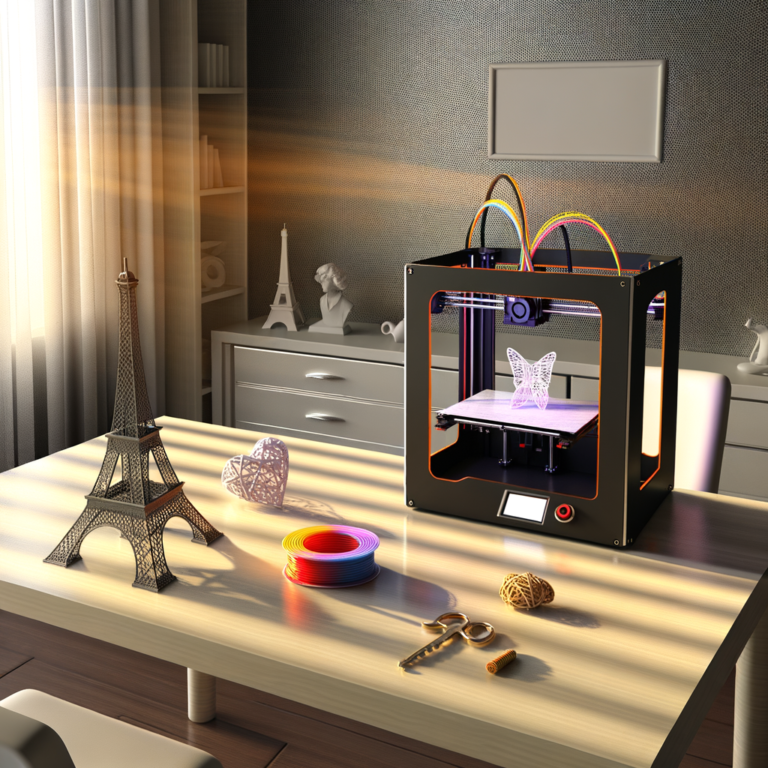

Alright, let's talk resin! If you've ever admired a 3D printed object and thought, "Wow, that's smoother than a baby's bottom," chances are it was made with resin. This material is the secret sauce for achieving high detail and a silky finish that can make your creations look like they just stepped out of a sci-fi movie. Resin printing is like the fine wine of 3D printing—it's got that extra touch of elegance and sophistication.

So, what's the deal with resin? First off, it's a liquid photopolymer that hardens when exposed to UV light, usually in a printer that looks like something straight out of a techie's dream. The magic happens layer by layer, creating intricate details that you just can't achieve with more traditional filament-based printing. Imagine crafting a miniature replica of the Eiffel Tower with all its delicate arches and latticework—resin is your go-to material for that kind of precision.

But it's not just about looks. Resin is a powerhouse when it comes to producing prototypes and detailed models. Whether you're an artist looking to capture every nuance of your sculpture or an engineer prototyping parts that need to fit just right, resin has got your back. The level of detail it offers is so impressive that it's often used in industries like dentistry for creating custom dental molds, and in jewelry-making for designing intricate pieces.

Now, let's be real—resin does have its quirks. It can be a bit of a diva in the 3D printing world. It's sticky, requires careful handling, and you need to cure it with UV light after printing. And, oh boy, does it have a distinctive smell! But for many, the payoff is worth it. Also, keep in mind that resin can be a bit pricier than other 3D printing materials, but if your project demands that level of detail and finish, the investment is well worth it.

In short, if you're aiming for detail and smoothness that could make a marble statue jealous, resin is your material. Just be ready to roll up your sleeves, maybe plug your nose, and dive into the fascinating world of resin 3D printing. Whether you're crafting a small-scale model or a prototype that needs to wow your boss, resin is all about turning your digital dreams into reality with a touch of class.

Factors to Consider When Choosing Materials

Alright, let's get down to the nitty-gritty of picking the right material for your 3D printing project. It's like choosing the perfect outfit for a party—you want to impress, but comfort is key, right? First things first, think about what you're making. Is it something that needs to withstand a bit of rough and tumble, like a part of a robot or a toy for your dog? Or maybe it's a delicate model of the Eiffel Tower for your desk? The intended use is your compass here.

Cost is another biggie. Let's face it, some materials can be as pricey as a designer handbag. You don't want to blow your entire budget on materials and have nothing left for that fancy new nozzle you've been eyeing. So, keep an eye on your wallet and consider the cost-effectiveness of each option. Sometimes, going for the slightly cheaper material that still ticks most of your boxes is the smart move.

Availability is another thing to keep in mind. You don't want to find the perfect material only to discover it's as rare as a unicorn. Check if it's readily available in your area or online and if it ships quickly enough for your timeline. Waiting weeks for a shipment can be a real buzzkill when you're eager to get printing.

And finally, let's talk about your printer. Just like how some shoes just don't go with certain outfits, not all printers play nice with every material. Make sure your printer can handle the material you choose. Some materials need higher temperatures or special nozzles, so double-check your printer's specs. It's all about finding that perfect match between your printer's capabilities and the material's requirements.

So, whether you're crafting a masterpiece or just tinkering around, keeping these factors in mind will help you choose the right material for the job. Happy printing!

Exploring Emerging Materials

Alright, folks, let's put on our futuristic goggles and dive into the exciting world of emerging 3D printing materials. It's like being on the brink of a sci-fi movie where the possibilities are endless, and trust me, they are! The world of 3D printing is evolving faster than a cat chasing a laser pointer. New materials are popping up like mushrooms after a rainstorm, and some of them are downright game-changers.

First up, let's talk about metal filaments. Yes, you heard that right—metal! Imagine printing with materials like stainless steel or even copper. These aren't just for show either; they're incredibly strong and can be used for making parts that need to withstand a bit of a beating. Think aerospace, automotive, and even jewelry. Who knew we'd be printing bling one day?

Now, for something a little more down-to-earth, but no less exciting: bioplastics. These are made from renewable resources and are biodegradable, making them a hit with the eco-conscious crowd. They promise a future where 3D printing is not just innovative but also sustainable. Imagine printing your garden gnome and knowing that if it ever breaks, it's not going to just sit in a landfill for eternity. That's the kind of future we can get behind!

And then there are conductive filaments. These are like the rockstars of the 3D printing world, allowing you to print circuits directly into your designs. Yes, we're talking about electronics that you can print at home! It's like turning your 3D printer into a mini factory for gadgets. The potential here is massive, from wearable tech to educational tools that could make learning about electronics as easy as pie.

Finally, we can't ignore the incredible world of composite materials. These are made by blending different materials to create something entirely new. Picture a filament that's part wood, part plastic, or even part carbon fiber. These composites offer unique properties like enhanced strength or a wood-like finish that can add a touch of nature to your projects. It's like having a Swiss army knife of materials at your disposal.

So, what's the takeaway here? The future of 3D printing materials is not just bright—it's dazzling. As these new materials continue to develop, they'll open up a whole new world of possibilities that we can't even fully imagine yet. It's an exciting time to be part of this 3D printing revolution, and who knows? Maybe your next project will be the one that changes the game. So go ahead, experiment, and let your imagination run wild!

Alright, let's wrap up our journey through the land of 3D printing materials! We've taken a whirlwind tour of everything from the eco-friendly charm of PLA to the industrial strength of ABS, the robust versatility of Nylon, and the smooth, intricate possibilities offered by Resin. Each material has its own unique personality and set of skills, just like the heroes in a comic book team-up.

Now, here's the thing: the "best" material is really the one that suits your specific needs. It's like picking a superhero sidekick. Do you need someone strong and reliable like ABS, or perhaps someone flexible and adaptable like TPU? The choice is yours, and it all depends on your project goals, budget, and the capabilities of your 3D printer.

Don't be afraid to experiment! The beauty of 3D printing is that it's as much about the journey as it is about the final destination. Try mixing things up, test different materials, and see what works best for you. Remember, every great inventor started with a bit of trial and error.

So, go ahead, unleash your creativity! Who knows, maybe you'll discover a new favorite material or even stumble upon an innovative solution that changes the game. Happy printing, and may your 3D creations be as amazing as your imagination!

Additional Resources

Alright, folks! You've made it this far, and you're practically a 3D printing material wizard now. But, as with any good adventure, there's always more to explore. So, let’s roll up our sleeves and dive into some extra goodies that’ll keep you ahead of the curve in the 3D printing universe.

First up, if you're itching for more in-depth reading, check out "The Ultimate Guide to 3D Printing Materials" by MakeXYZ. It’s like a treasure map for your 3D projects. You’ll find detailed breakdowns of each material's properties and nifty tips for optimizing your prints. Trust me, your future self will thank you!

If you're more of a visual learner, YouTube is your best pal. Channels like "3D Printing Nerd" and "Makers Muse" offer video tutorials and reviews that are both informative and entertaining. They make learning feel like a Netflix binge, minus the guilt!

Now, for those of you who love a good chat, dive into online communities like Reddit’s r/3Dprinting and the 3D Printing Forums. These places are bustling with fellow enthusiasts sharing their successes, failures, and everything in between. It’s like having a round-the-clock support group that speaks fluent filament.

And hey, if you're looking to get a bit hands-on and maybe even flex those networking muscles, consider attending 3D printing expos or workshops. Events like the TCT Show or Formnext are gold mines for discovering the latest trends and tech. Plus, you might just bump into your next collaboration partner!

Finally, don't forget to keep an eye out for emerging materials and techniques. Websites like 3D Printing Industry and All3DP are fantastic for staying updated with the latest and greatest in the field. They’re like having a crystal ball, but for 3D printing.

So there you have it! A treasure trove of resources to keep you inspired and informed. Remember, the world of 3D printing is vast and ever-changing, so stay curious and keep experimenting. Who knows? Your next print could be the next big thing! Happy printing!